Two For One Twister for Spun

| Two For One Twister for Spun TECHNICAL SPECIFICATION | ||

|---|---|---|

| Type | Double side & single deck | |

| Model | JIGAR 150 HS - SP/EC | |

| Yarn | Spun, Cotton, Filament & Viscose | |

| Pot dia | 150 mm | |

| Count range | 2/16 to 2/80 | |

| No. of spindles Max. | 240 | |

| No. of spindles / Section | 12 | |

| Spindle gauge | 256 mm | |

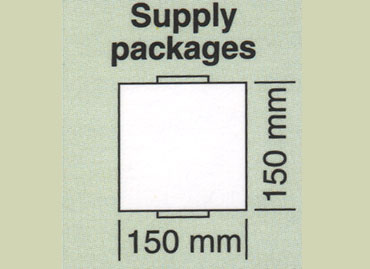

| Feed packege Cone/cheese Tube in side dia Max. out side dia Conicity |

900 gram 170 mm leangth 43 mm 150 mm 3 30'/ 4 20' or cheese |

|

| Twister range | 2.5 to 43 TPI | |

| Spindle speed Max | 14000 RPM (as per count) | |

| Effective twist insertion | 28000 | |

| Spindle drive | Tangential belt | |

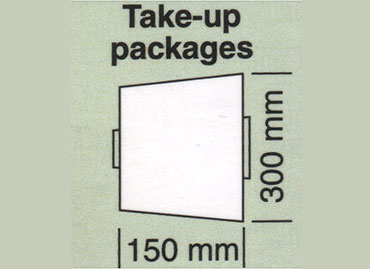

| Delivery package Traverse length Cone / cheese length Max. dia. Conicity |

3.0 kg. 150 mm 170 mm 300 mm 3 30'/ 4 20'/ 5 57' cheese |

|

| Starting system | Slow start by inverter drive | |

| Twist direction | S & Z selectable | |

| Supply package stabilization | Megnet system | |

| Tension device | Capsule type | |

| Optional | Balloon limiter Waxing device Oil attachment Tail end bunching device Individual-Spindle motor drive |

|

OUT STANDING FEATURES: |

||

|

||

Characteristics

Balloon Limiter (Option)

It is a device of which surface is specially treated smoothly and which can provide high-speed revolution in order todecrease power and increase productivith by making balloon small in case of large balloon.

Cradle

All the cones with cone angle within the range of 0º 0'~5º 57' can be used by changing cone holder. Adjusting of the cradle is simple and take-up can be done up to 300 mm.

Electronic Driving System (Option)

It is possible to set the RPM, T/M, lease ANGLE, and take-up LENGTH without changing the gears by electronic control of the machine with utilizing the inverter and electronic driving system, It saves power energy and check exactly all running condition through HMI.

Spindle

Roller Bearing type bolster is used which exhibits excellent durability even for high speed rotation and high-precision for hard ceramic is applied to all the yarn passages for the ideal balloon formation and good quality of the products.

Motor Box

All the switches and the indicators are collected in one panel, operation of the machine and observation of the operating state are easy and convenient.

Auto-Tensioning Device

Appropriate tensioning is achieved automatically by tangential and in case there is a change in twist direction the magnitudes of tension of both belts are adjusted automatically and a special device is attached to absorb the shock due to load variation.

| No. of Spindle | 180 | 192 | 204 |

216 | 228 | 240 |

| No. of Section | 15 | 16 | 17 | 18 | 19 | 20 |

| Machine length (Mtr.) | 25 | 26.53 | 28.06 | 29.59 | 31.12 | 32.65 |

| Machine width | 750 mm | |||||